E-PROPS GLORIEUSE : Range of In-Flight Variable Pitch Propellers for ROTAX serie 9xx

E-PROPS CONSTANT SPEED PROPELLERS GLORIEUSE

GLORIEUSE = range of 3-blade in-flight variable pitch tractor propellers (Constant Speed) : very strong, ultra-light, high-performance, reducing vibrations and noise to a minimum. The TOP Constant Speed propellers for ROTAX engines !!!

ALL INFORMATION HERE :

1 - GLORIEUSE : Description

2 - Governors and Regulators solutions according to Rotax configurations

3 - GLORIEUSE Manuals

4 - Assembly & Installation Videos

5 - E-PROPS Governor

6 - E-SCREEN Regulator

7 - Data Sheets (PDF)

8 - CAD files (stp)

9 - Prices

10 - Tests, comparatives, videos, pictures

11 - FAQ GLORIEUSE

1- GLORIEUSE : Description

✗ 3-blade propellers, in-flight variable pitch system (Constant Speed), the lighest on the market

✗ For tractor aircraft only (for pusher aircraft, under development)

✗ For gear-drive engines (on a Rotax 9xx base) up to 185 hp

✗ ROTAX 912 912S 912ULS 912iS 914 915iS 916iS as well as conversions based on these engines (EDGE PERFORMANCE, EPA POWER...)

✗ For configuration 2 (electric and fixed pitch) AND configuration 3 (hydraulic).

✗ Work with other governors (MT-Propellers, JIHOSTROJ...) and other regulators (FLYBOX APR-1, RS FLIGHT SYSTEMS...)

✗ Versions and Diameters :

- Blades C8 : Rotax 912 / 912S & iS / 914 / 915iS : from 160 to 190 cm (each 5 cm) / from 63" to 74,8" (each 2")

- Blades C9 : Rotax 915iS & 916iS : 175 cm, 190 cm, 210 cm / 68.9", 74.8", 82.7"

✗ Max RPM at propeller = 2.600 (for the 170 cm diameter model)

✗ Moment of inertia : 2.600 kg.cm² (for the 170 cm diameter model)

✗ Hydraulic actuator with electronic management : the robustness of the hydraulic actuator and the precision of the electronics

✗ No bearing = no jamming / No lubricant = no leakage

✗ Ultra-fast regulation: max pitch / min pitch in less than 3 seconds, without jerks or speed variations

✗ Safety stops min. pitch / max. pitch

✗ Pitch variation: max. range 16° (20° in option)

✗ Total weight: 3-blade propeller + governor + regulator + spinner = only 4 kg / 8,8 lb

✗ Carbon propellers with Titanium leading edge

✗ Very strong : 100% carbon, very high fibers ratio, RTM Manufacturing

✗ No cyclic loading on aluminium components = no cracks

✗ Compliant with ASTM F2506-13 / EASA CS-P certification in progress

✗ TBO = 2000 hrs

GLORIEUSE GLOR-3-175-C9-T on SHARK EDGE PERFORMANCE

The design of the GLORIEUSE variable pitch propeller blade is very aesthetic, but above all it reduces the pitch control efforts. This allowed E-Props to realize a low pressure hydraulic control (2 bars), thus to lighten the whole control system, with a small cylinder.

special blades profiles

Why different blades ?

Apart from the difference in engine power, a Rotax 912S has a 1:2.43 gearbox, while a Rotax 916iS has a 1:2.54 gearbox.

The propeller therefore doesn't turn at the same rpm. The same blade couldn't have the same efficiency on both engines.

To have a high-performance propeller, it has to be exactly matched to the engine, its gearbox and the ideal diameter for each aircraft.

That's why E-PROPS offers a range of different blade models, declined (and not recut) in different diameters.

left to right : Glorieuse C8 (912S) / Glorieuse C9 (916iS)

2- Governors and Regulators solutions according to Rotax configurations

Reminder: Rotax engine configurations

✗ Rotax S2 (Configuration 2) means that the propeller shaft in the gearbox is not configured for a Constant Speed hydraulic governor (large hole in the center for the 912, 912S and 914). This is the most common and slightly less expensive version of Rotax 4-stroke engines.

✗ Rotax S3 (Configuration 3) means that the gearbox is pre-equipped for mounting a hydraulic governor.

Possible solutions for Glorieuse propeller control :

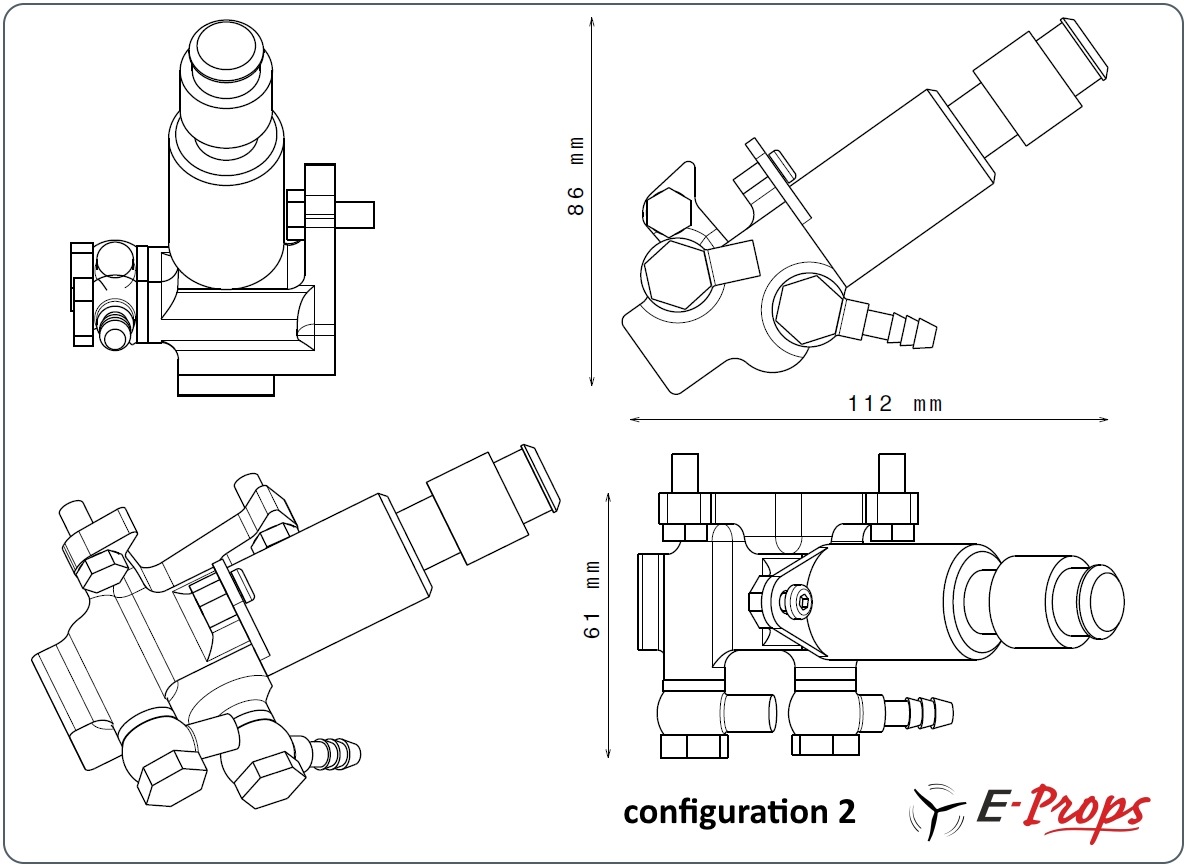

For Rotax 912-912S-914 engines, configuration 2 (S2):

- Governor electro-hydraulic actuator E-Props + regulator E-Screen (electronic) => option recommended by E-Props

- Governor electro-hydraulic actuator E-Props + regulator FLYBOX APR-1 (electronic)

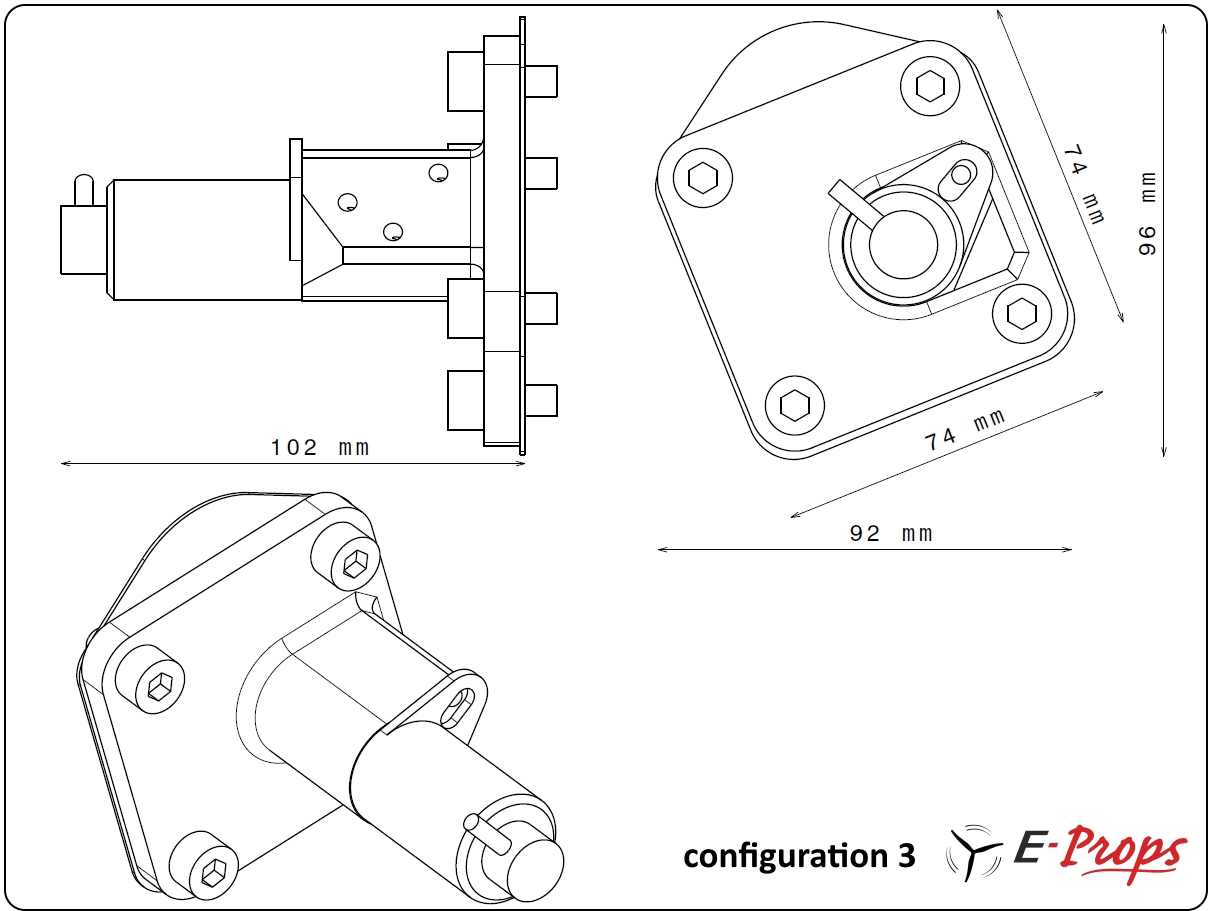

For Rotax engines 912-912S-914-915is-916is configuration 3 (S3):

- Governor electro-hydraulic actuator E-Props + regulator E-Screen (electronic) => option recommended by E-Props

- Governor electro-hydraulic actuator E-Props + regulator FLYBOX APR-1 (electronic)

- Governor hydraulic actuator MT-Propellers or JIHOSTROJ => 100% mechanical solution

Please note: RS Flight Systems and Flybox Innovative Avionics offer “Single Lever” solutions for hydraulic governors (please consult these companies).

E-Props is working on a Single Lever system - coming soon.

For Rotax 915is-916is engines, configuration 2 (S2):

To date, there is no solution for this configuration, but it is easily possible to transform configuration 2 into 3.

3- GLORIEUSE Manuals

Installation and Maintenance Manuals of Glorieuse, Governor and Regulator :

| Propeller : Installation and Maintenance Manual | EP-IMM-glorieuseID1891_00102.pdf |

| Hydraulic propeller governor configuration 2 | EP-IMM-glorieuse-conf2ID1893_00101.pdf |

| Hydraulic propeller governor configuration 3 for E-Props regulator only | EP-IMM-glorieuse-conf3ID1894_00101.pdf |

| Hydraulic propeller governor (configuration 3 high pressure for non E-props governor) | EP-IMM-glorieuse-conf3HPID1892_00101.pdf |

| Regulator E-Props | EP-IMM-glorieuse-regulatorID1895_00102.pdf |

| Flying with a Constant Speed Propeller | Flying with a CS Propeller.pdf |

4- Assembly & Installation Videos

Assembly of GLORIEUSE propellers range - Very simple

ASSEMBLY of GLORIEUSE Constant Speed Propeller (English Version)

MOUNTING GLORIEUSE Propeller on Rotax engine (English Version)

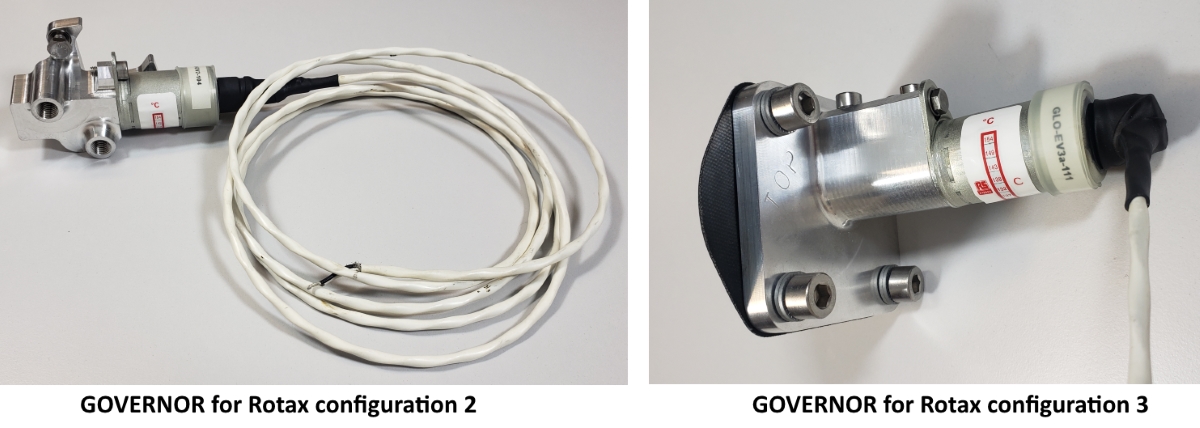

5- E-PROPS Governor

Hydraulic actuator with electronic management

The robustness of the hydraulic actuator and the precision of the electronics

Two different systems according to the Rotax configuration :

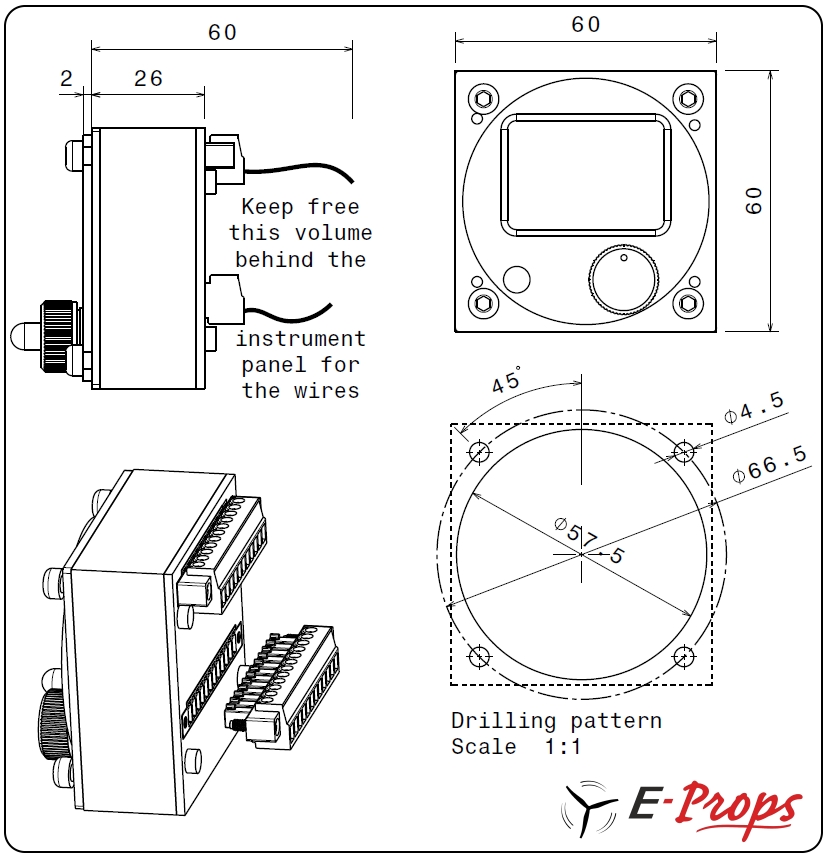

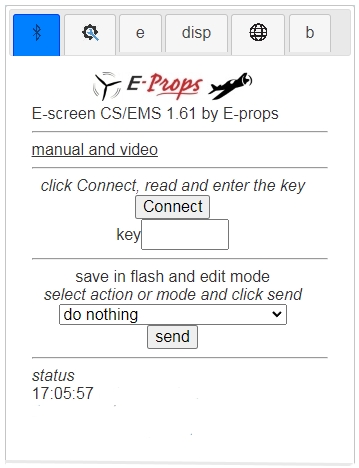

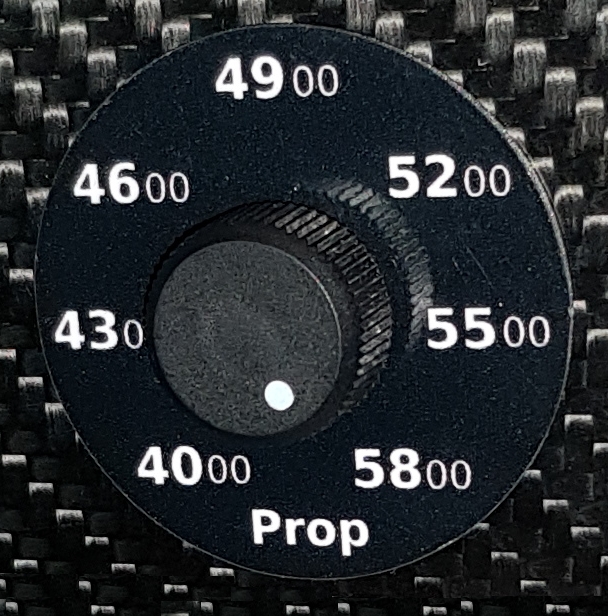

6- E-SCREEN Regulator

E-SCREEN : specific instrument for Constant Speed propeller, designed and manufactured by E-PROPS, adapted for GLORIEUSE in-flight variable pitch propellers range. The best solution to control the propeller for a high reactivity.

RPM adjustment potentiometer, intake pressure

Diameter = 57 mm (2.24 inch)

Weight = 70 g

Automatic over-torque and over-rpm protection

Setting via Bluetooth => see below

High readability screen

Use of the E-Screen regulator - in English

click here : Setting the E-SCREEN parameters

------------------------------

If you only want to change the pitch on the control panel, we also offer the POTIENTIOMETER.

It's the same system as the E-SCREEN, but without the display, which can be easier to integrate on some control panels.

7- DATA SHEET (PDF)

Click on the pictures to see the PDF files :

DATA SHEET GLORIEUSE C8 for 912 / 912S / 914 |

DATA SHEET GLORIEUSE C9 for 915iS / 916iS |

8- CAD files (stp)

For obvious reasons of design confidentiality, the files of the blades below are not the exact blade shapes.

They are provided for marketing rendering on CAD of aircraft / engines fairings.

They should not be used for efficiency calculations.

GLORIEUSE inflight variable pitch models :

- Blade ref U372 (length 875 mm / C8) : Blade U372 stp

- Blade ref U374 (length 875 mm / C8) : Blade U374 stp

- Blade ref U392 (length 950 mm / C8) : Blade U392 stp

- Blade ref U394 (length 950 mm / C9) : Blade U394 stp

Spacers (see details on this page : ESU SPACERS) :

- E-PROPS ESU spacers : SPACER stp

Instrument E-Screen (for Glorieuse propellers) :

- E-PROPS E-SCREEN : E-SCREEN stp

STP files of E-Props spinners and spacers (V20 range) are the exact shapes.

Spinners (see details on this page : E-PROPS SPINNERS) :

- diameter 210 mm : Spinner 210 stp

- diameter 220 mm : Spinner 220 stp

- diameter 230 mm : Spinner 230 stp

- diameter 240 mm : Spinner 240 stp

- diameter 250 mm : Spinner 250 stp

- diameter 260 mm : Spinner 260 stp

- diameter 270 mm : Spinner 270 stp

- diameter 280 mm : Spinner 280 stp

- diameter 290 mm : Spinner 290 stp

- diameter 300 mm : Spinner 300 stp

- diameter 310 mm : Spinner 310 stp

- diameter 320 mm : Spinner 320 stp

- diameter 340 mm : Spinner 340 stp

- diameter 360 mm : Spinner 360 stp

- diameter 380 mm : Spinner 380 stp

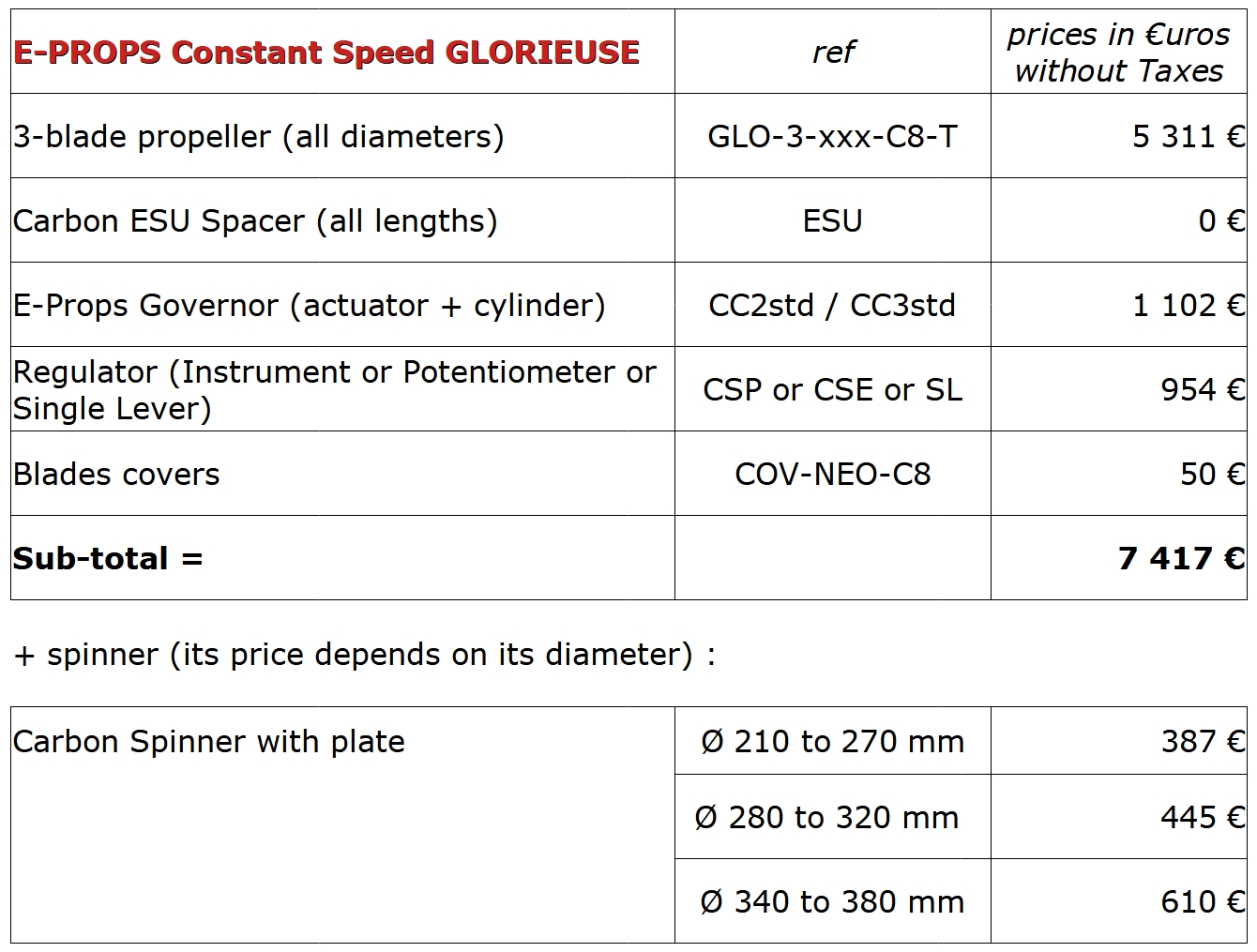

9- Prices

The E-PROPS Glorieuse propeller is supplied with all the necessary accessories: spacer, complete governor, regulator (instrument or potentiometer or Single Lever), spinner, blade protection covers and assembly tool kit.

No other components are required for assembly and adjustment of the Glorieuse propeller.

prices 2025

Compatible accessories:

- E-PROPS SPACERS : 38 lengths of ultra-light spacers available, from -20 mm to + 170 mm

- E-PROPS SPINNERS : 13 diameters available, from 230 mm to 380 mm.

10- Tests, comparatives, videos, pictures

Clik on this link :

GLORIEUSE : PROPELLER TESTS & COMPARISONS

11 - FAQ GLORIEUSE

The most frequent question concerns clearance in the blade root.

Why can a slight blade movement be felt on the ground ?

A small blade root clearance is inherent to the design of all variable-pitch and in-flight adjustable propellers. During the first hours of operation (typically 10–20 hours), a slight evolution of this clearance may occur as part of the normal bedding-in of mechanical interfaces under operational loads.

Is this clearance within acceptable limits ?

Yes. The blade root clearance on the E-Props Glorieuse propeller is fully compliant with its design and certification specifications and is not greater than that of comparable propellers on the market. All tolerances are clearly defined in the Maintenance Manual.

Blades should be tight in the propeller hub, the play between the blades and the hub must not be bigger than 0,3mm.

And the blade tip displacement must not be bigger than 13mm (wobble).

measure of the clearance

measure of the clearance

Why does the clearance seem more noticeable on the Glorieuse propeller ?

The Glorieuse propeller is significantly lighter than many competing propellers. Its low mass and inertia make blade movement easier to perceive by hand at the blade tip when the aircraft is on the ground. This can give the impression of increased play, although the actual clearance remains unchanged and within specified limits.

Does this clearance affect safety, performance, or durability ?

No. This blade root clearance has no negative impact on safety, performance, or service life. When operated and maintained in accordance with the Manual, it is stable and non-progressive beyond the initial bedding-in phase.

Could the observed movement come from the engine rather than the propeller ?

Yes. Some engines equipped with a reduction gearbox exhibit a noticeable gearbox backlash. This backlash is a normal characteristic of the engine and must not be confused with blade movement within the propeller hub.

Click on the following links to see some videos on normal clearances in the blade roots of GLORIEUSE :

- clearance video 01

- clearance video 02

- clearance video 03

- clearance video 04

- clearance video 05

At E-Props, the design department and test pilots made many tests with a lot more clearance.

After a couple of flight hours, when sleeves find their positions, the mechanical clearance is stabilized for hundreds of hours.

Anyway, you can regularly check the torque on the M6 bolts.