Réglage du calage des pales des hélices E-PROPS

Les hélices à pas réglable au sol E-PROPS possèdent un fort effet ESR. Leur comportement est similaire à celui d'une hélice à pas variable en vol : haute efficacité de la combinaison moteur-hélice sur toute la plage de vitesse de votre avion.

⇒ Pour obtenir cet effet ESR, le réglage du pas des pales doit être subtil et précis.

IMPORTANT:

La mesure du régime moteur idéal se fait en vol et non au sol. Pour les modèles E-Props à pas réglable au sol, qui ont un fort effet ESR, la mesure du régime statique n'est pas une donnée significative, car ces hélices sont conçues pour atteindre leur pleine traction ou poussée juste après le début du roulement au décollage, et non en statique. En statique, les pales des E-Props sont légèrement décrochées.

L'ajustement du calage des pales dépend du type de moteur de l'aéronef.

1 - Comment régler le calage des pales E-PROPS

2 - Réglage E-Props sur moteurs Rotax 4T série 9xx

3 - Réglage E-Props sur moteurs Rotax 2T 582

1 - Comment régler le calage des pales E-PROPS

La meilleure solution pour régler le pas des pales des hélices E-Props est de visionner la vidéo ci-dessous.

Vous pouvez également consulter les MANUELS

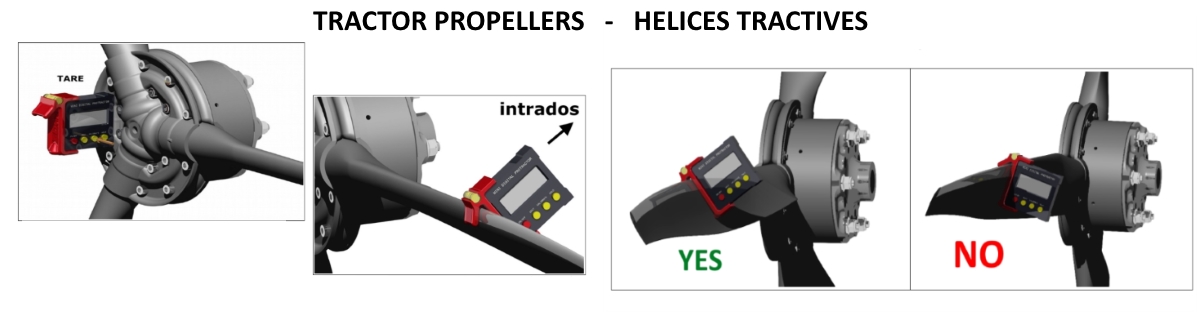

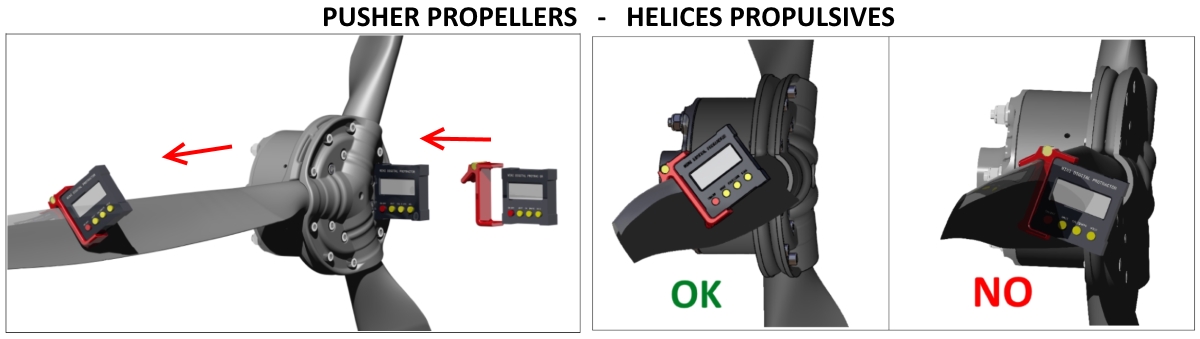

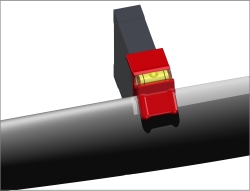

Ci-dessous vous pouvez voir comment positionner l'outil de réglage numérique E-Props, fortement recommandé pour ajuster le pas des pales.

positionner l'outil au bord du blindage Titane

2 - Réglage E-Props sur moteurs Rotax 4T série 9xx

Sur les moteurs Rotax 4 temps série 9xx (912, 912S, 912iS, 914, 915iS), le calage pour lequel l'hélice E-PROPS va donner les meilleures performances sur toute la plage de vitesse de l'aéronef est obtenu à:

5.500 tr/min plein gaz, vol en palier

PROCEDURE:

1/ Ajuster le pas avec le calage recommandé indiqué sur la Fiche d'Identification (remise avec l'hélice), ou dans la

description de l'hélice dans notre catalogue

Voir l'article: avion + moteur + réducteur + hélice.

Exemple: 3-pale Durandal 175 cm DUR-3-175-C4-T

pour ICP Savannah Rotax 912S réducteur 2.43.

1er calage recommandé = 25°

, ou bien contactez notre équipe. Exemple: 3-pale Durandal 175 cm DUR-3-175-C4-T

pour ICP Savannah Rotax 912S réducteur 2.43.

1er calage recommandé = 25°

Le calage recommandé est une simple indication, pas une obligation. Une mesure du pas faite différemment, l'état du moteur, etc, peuvent changer cette valeur.

2/ Au sol, mettre pleine puissance sur freins ou cales.

- Si vous avez entre 5.000 et 5.800 tr/min, vous pouvez aller poursuivre les essais en vol.

- Si ce n'est pas le cas, ajuster le calage des pales pour avoir entre 5.000 et 5.800 tr/min au sol.

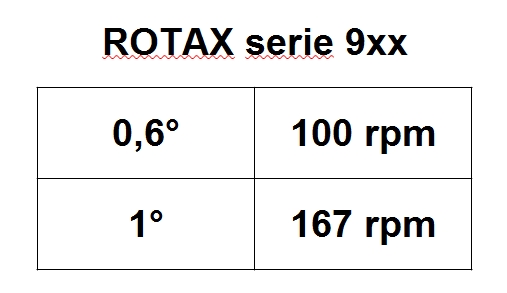

Augmenter le pas de 0,6° réduit le régime de 100 tr/min.

Réduire le pas de 0,6° augmente le régime de 100 tr/min.

3/ En vol, se mettre en palier à une altitude de croisière (en dessous de 10.000 ft / 3.000 ft convient très bien).

- Mettre plein gaz.

- Noter le nombre de tr/min qui s'affiche sur votre compte-tours.

- Si vous avez 5500 tr/min (+/- 50 tr/min), votre réglage est parfait.

- Sinon, posez-vous et refaites le réglage.

Exemple : en palier plein gaz, le moteur tourne à 5.700 tr/min, alors que l'on vise 5.500 tr/min.

La différence est de 2 x 100 tr/min : il faut donc augmenter le calage de 2 x 0,6° = 1,2°.

Si vous obtenez cette valeur de 5.500 tr/min en palier plein gaz, alors votre hélice est réglée de façon optimale pour toute la plage de vitesse de votre aéronef.

Bien sûr, cela ne signifie pas qu'il faille toujours voler en croisière à 5.500 tr/min: c'est seulement la bonne valeur pour obtenir le meilleur calage.

3 - Réglage E-Props sur moteurs Rotax 2T 582

Sur les moteurs Rotax 2 temps (532, 582), le calage pour lequel l'hélice E-PROPS va donner les meilleures performances sur toute la plage de vitesse de l'aéronef est obtenu à:

6.800 tr/min plein gaz, vol en palier

PROCEDURE:

1/ Ajuster le pas avec le calage recommandé indiqué sur la Fiche d'Identification (remise avec l'hélice), ou dans la

description de l'hélice dans notre catalogue

Voir l'article: avion + moteur + réducteur + hélice.

Exemple: 3-pale Durandal 175 cm DUR-3-175-C4-T

pour ICP Savannah Rotax 912S réducteur 2.43.

1er calage recommandé = 25°

, ou bien contactez notre équipe. Exemple: 3-pale Durandal 175 cm DUR-3-175-C4-T

pour ICP Savannah Rotax 912S réducteur 2.43.

1er calage recommandé = 25°

Le calage recommandé est une simple indication, pas une obligation. Une mesure du pas faite différemment, l'état du moteur, etc, peuvent changer cette valeur.

2/ Au sol, mettre pleine puissance sur freins ou cales.

- Si vous avez entre 6.000 et 6.800 tr/min, vous pouvez aller poursuivre les essais en vol.

- Si ce n'est pas le cas, ajuster le calage des pales pour avoir entre 6.000 et 6.800 tr/min au sol.

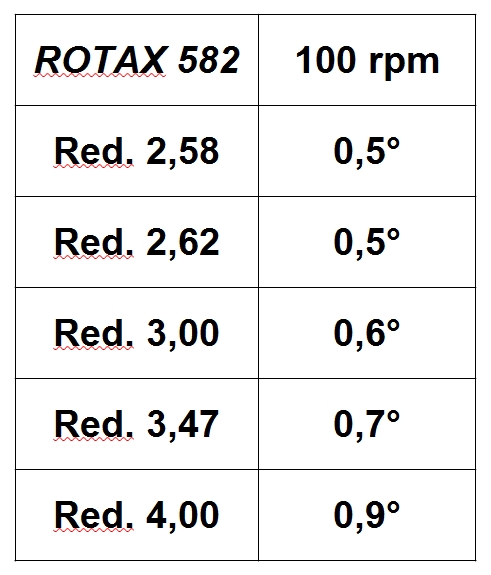

Augmenter le pas de 0,5° à 0,9° (la valeur dépend du réducteur - voir tableau ci-dessous) réduit le régime de 100 tr/min.

Réduire le pas de 0,5° à 0,9° (la valeur dépend du réducteur - voir tableau ci-dessous) augmente le régime de 100 tr/min.

3/ En vol, se mettre en palier à une altitude de croisière (en dessous de 10.000 ft / 3.000 ft convient très bien).

- Mettre plein gaz.

- Noter le nombre de tr/min qui s'affiche sur votre compte-tours.

- Si vous avez 6800 tr/min (+/- 50 tr/min), votre réglage est parfait.

- Sinon, posez-vous et refaites le réglage.

Exemple : en palier plein gaz, le moteur tourne à 6.600 tr/min, alors que l'on vise 6.800 tr/min.

La différence est de 2 x 100 tr/min : il faut donc réduire le calage de 2 x 0,7° = 1,4°.

Si vous obtenez cette valeur de 6.800 tr/min en palier plein gaz, alors votre hélice est réglée de façon optimale pour toute la plage de vitesse de votre aéronef.

Bien sûr, cela ne signifie pas qu'il faille toujours voler en croisière à 6.800 tr/min: c'est seulement la bonne valeur pour obtenir le meilleur calage.

A noter : Si vous avez des valeurs incohérentes par rapport aux valeurs données par E-Props, vérifiez si vous avez bien le bon réducteur. Il est fréquent que les carters de réducteurs des moteurs 582 affichent un rapport de réduction, mais que les engrenages ne soient pas les bons à l'intérieur du carter. Vérifiez également votre compte-tours si celui-ci est à aiguilles (souvent mal étalonné).

Ce qui fait décoller l’avion, ce n’est pas le régime moteur, mais la traction de l’hélice.