E-PROPS: Certification EASA / DGAC, ASTM F2506-13, Service Letters, Bulletins Services,

Les hélices E-PROPS sont depuis toujours conçues, puis fabriquées et testées afin de répondre aux exigences des normes aéronautiques.

La qualité et la sécurité sont pour E-PROPS des préoccupations permanentes tout au long de la conception, des approvisionnements, de la fabrication, des essais et de la commercialisation de ses produits.

1- CERTIFICATION DGAC / EASA

1- CERTIFICATION DGAC / EASA

2- ASTM F2506-13 (LSA)

3- SERVICE LETTERS

4- BULLETINS SERVICE

Fin 2021, E-PROPS a entamé les procédures suivantes :

- auprès de la DGAC, demande d'un Agrément d'Organisme de Production (POA) selon le règlement EASA Part 21 sous-partie G (en cours d'instruction)

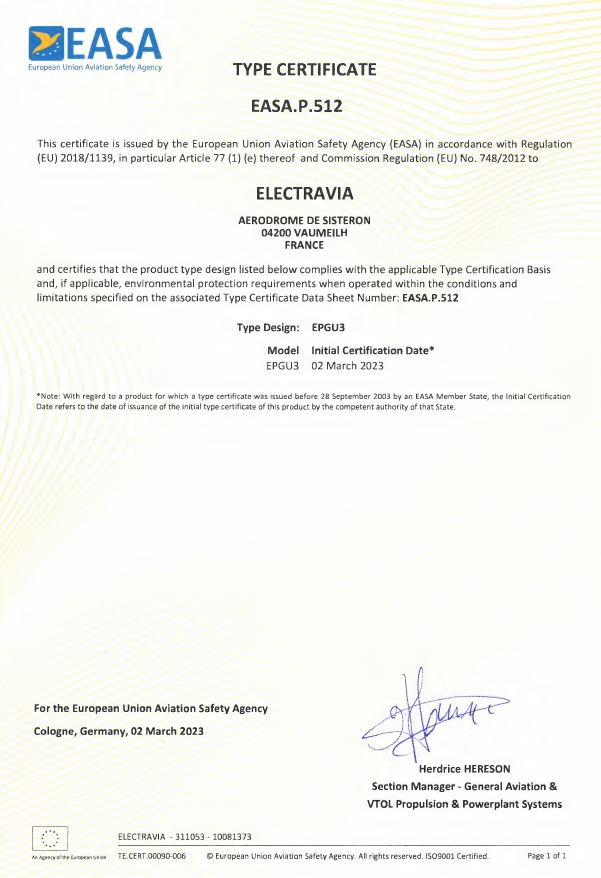

- auprès de l'EASA, demande de Certificats de Type Hélice (Type Certificates) pour certains modèles d'E-Props adaptés à utilisation sur avions certifiés

EASA Type Certificates:

✗ EASA P.512 (EPGU3) daté du 02 Mars 2023

EASA Type Certificates:

✗ EASA P.512 (EPGU3) dated 02 March 2023

Les hélices E-PROPS (gammes DURANDAL, EXCALIBUR, GLORIEUSE) répondent à la norme ASTM F2506-13 pour les aéronefs légers LSA (Light Sport Aircraft).

La norme ASTM F2506-13 établit des exigences minimales pour la conception, les essais et l’assurance qualité des hélices à pas fixe ou réglables au sol pour les aéronefs légers sous réglementation LSA (Light Sport Aircraft). Essais de traction, mesures de la tenue mécanique, essais de résistance à la fatigue, essais d’endurance et inspections de démontage ont été effectués pour répondre aux exigences prescrites.

Declarations of Compliance to ASTM F2506-13 :

✗ Gamme DURANDAL

✗ Gamme EXCALIBUR

✗ Gamme GLORIEUSE

Une "Service Letter" est émise pour attirer l'attention sur une information.

- V20-Replacement of M4 screws - 27-03-2023

- Changement du système de numérotation - Séries Durandal - 02-03-2022

Les Bulletins de Service sont édités par les fabricants de produits aéronautiques. Ils sont établis afin de prévenir les utilisateurs d'un problème technique, d'une nouveauté ou d'une amélioration du produit aéronautique, ainsi que pour transmettre une information technique concernant l'utilisation du produit aéronautique.

Les Bulletins Service de E-PROPS sont consultables ci-après.

BULLETIN SERVICE BS REF HEP-BS-20-001F

Date: 11 janvier 2020

Objet du BS: Rappel des consignes de montage, serrage et vérification des vis de fixation du moyeu de l'hélice EXCALIBUR-6 V12 sur autogires [1/2]

BS: HEP-BS-20-001F.pdf

BULLETIN SERVICE BS REF HEP-BS-20-002F

Date: 21 janvier 2020

Objet du BS: Rappel des consignes de montage, serrage et vérification des vis de fixation du moyeu de l'hélice EXCALIBUR-6 V12 sur autogires [2/2]

BS: HEP-BS-20-002F.pdf

==> Document DGAC : BULLETIN d'INFORMATION DGAC REF BI 2020-ULM-01 Révision 1

La qualité et la sécurité sont pour E-PROPS des préoccupations permanentes tout au long de la conception, des approvisionnements, de la fabrication, des essais et de la commercialisation de ses produits.

2- ASTM F2506-13 (LSA)

3- SERVICE LETTERS

4- BULLETINS SERVICE

1- CERTIFICATION DGAC / EASA

Fin 2021, E-PROPS a entamé les procédures suivantes :

- auprès de la DGAC, demande d'un Agrément d'Organisme de Production (POA) selon le règlement EASA Part 21 sous-partie G (en cours d'instruction)

- auprès de l'EASA, demande de Certificats de Type Hélice (Type Certificates) pour certains modèles d'E-Props adaptés à utilisation sur avions certifiés

EASA Type Certificates:

✗ EASA P.512 (EPGU3) daté du 02 Mars 2023

EASA Type Certificates:

✗ EASA P.512 (EPGU3) dated 02 March 2023

2- ASTM F2506-13 (LSA)

Les hélices E-PROPS (gammes DURANDAL, EXCALIBUR, GLORIEUSE) répondent à la norme ASTM F2506-13 pour les aéronefs légers LSA (Light Sport Aircraft).

La norme ASTM F2506-13 établit des exigences minimales pour la conception, les essais et l’assurance qualité des hélices à pas fixe ou réglables au sol pour les aéronefs légers sous réglementation LSA (Light Sport Aircraft). Essais de traction, mesures de la tenue mécanique, essais de résistance à la fatigue, essais d’endurance et inspections de démontage ont été effectués pour répondre aux exigences prescrites.

Declarations of Compliance to ASTM F2506-13 :

✗ Gamme DURANDAL

✗ Gamme EXCALIBUR

✗ Gamme GLORIEUSE

3- SERVICE LETTERS

Une "Service Letter" est émise pour attirer l'attention sur une information.

- V20-Replacement of M4 screws - 27-03-2023

- Changement du système de numérotation - Séries Durandal - 02-03-2022

4- BULLETINS SERVICE

Les Bulletins de Service sont édités par les fabricants de produits aéronautiques. Ils sont établis afin de prévenir les utilisateurs d'un problème technique, d'une nouveauté ou d'une amélioration du produit aéronautique, ainsi que pour transmettre une information technique concernant l'utilisation du produit aéronautique.

Les Bulletins Service de E-PROPS sont consultables ci-après.

BULLETIN SERVICE BS REF HEP-BS-20-001F

Date: 11 janvier 2020

Objet du BS: Rappel des consignes de montage, serrage et vérification des vis de fixation du moyeu de l'hélice EXCALIBUR-6 V12 sur autogires [1/2]

BS: HEP-BS-20-001F.pdf

BULLETIN SERVICE BS REF HEP-BS-20-002F

Date: 21 janvier 2020

Objet du BS: Rappel des consignes de montage, serrage et vérification des vis de fixation du moyeu de l'hélice EXCALIBUR-6 V12 sur autogires [2/2]

BS: HEP-BS-20-002F.pdf

==> Document DGAC : BULLETIN d'INFORMATION DGAC REF BI 2020-ULM-01 Révision 1