E-PROPS CLARENT CCW : Carbon-Titanium Propellers for Direct-Drive Engines

E-PROPS CLARENT GROUND-ADJUSTABLE PROPELLERS

CLARENT = a range of 2-blade and 3-blade counter-clockwise (CCW) ground-adjustable propellers: extremely strong, lightweight, high-performance, reducing vibrations and noise to the maximum.

The TOP ground-adjustable propellers for LYCOMING & CONTINENTAL direct-drive engines in pusher configuration!!!

Multi-objective optimization for high aerodynamic efficiency, minimal weight, superior strength, and noise reduction

|

|

|

|

1 - CLARENT CCW: Description

2 - Accessories

3 - CLARENT Program Progress

4 - Propeller torsional vibration analysis on Lycoming O-360

1- CLARENT: Description

✗ 2-blade & 3-blade ground-adjustable carbon propellers with titanium leading-edge protection

✗ For aircraft in pusher configuration, CCW rotation direction (counter-clockwise)

✗ Innovative blade airfoils

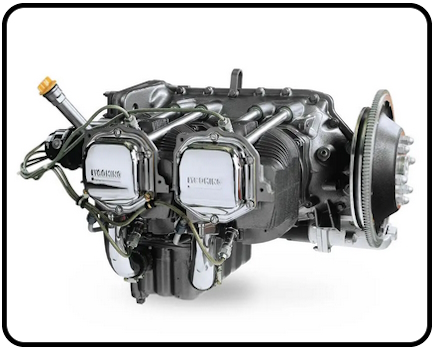

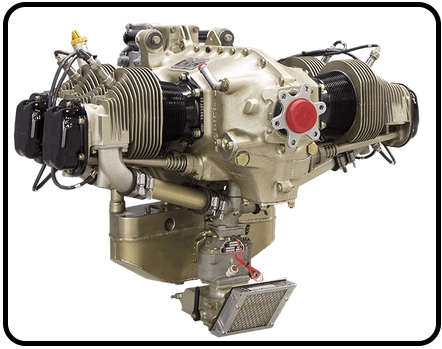

✗ For direct-drive Lycoming & Continental engines from 100 to 270 hp:

- 4 cylinders: up to 210 hp

Continental O-200 O-240 IO-240

Lycoming O-235 O-320 O-360 IO-360 IO-390

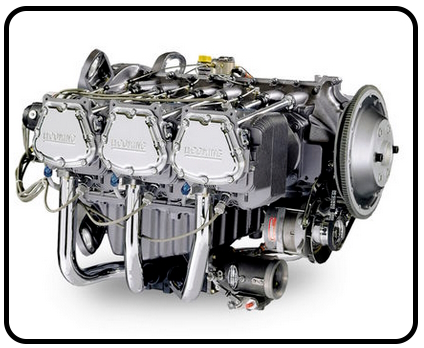

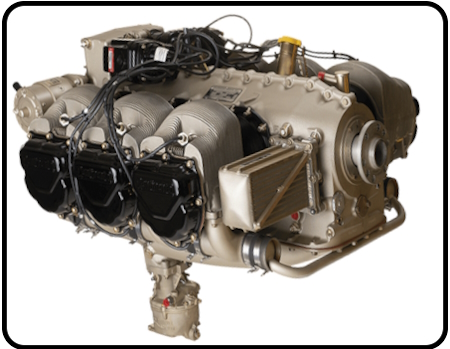

- 6 cylinders: up to 270 hp

Continental C145 O-300 O-360 O-470 IO-470

Lycoming O-540 IO-540

Propeller range for Lycoming & Continental engines =>

✗ Diameters: from 140 cm to 210 cm

✗ 2-blade weight = 6 kg

✗ 3-blade weight = 7 kg

✗ Bolt patterns = SAE1 & SAE2

✗ Max RPM = 3,300 rpm

✗ Moment of inertia: 6000 kg.cm² (for 190 cm diameter models)

Same moment of inertia as wooden propellers for the same engines.

✗ VHR carbon propellers [Very High Resistance] with titanium leading-edge protection

✗ Extremely strong: 100% carbon, very high fiber content, RTM manufacturing process

✗ No cyclic load on aluminum components = no cracks

2- Accessories

✗ Carbon cones: diameters from 300 mm to 380 mm

✗ Integrated carbon spacers: lengths from -15 mm to 230 mm, every 5 mm

3- CLARENT Program Progress

Ground-adjustable propellers dedicated to Lycoming and Continental engines in pusher configuration — for example for aircraft from the RUTAN family (VariEze, LongEze, Cozy, etc.) — are currently undergoing a specific development by our team.

These models represent a major step forward in optimizing the performance and efficiency of this type of aircraft, which we particularly appreciate at E-PROPS.

We know that many pilots are eagerly waiting for them: that is precisely why we pay special attention to the design and mechanical strength calculations. Once this stage is completed, production will require the manufacturing of dedicated molds and tooling, in order to ensure a build quality matching the expected reliability standards. Then, essential testing will follow to fully validate these new propellers in real operating conditions.

=> E-PROPS’ objective is clear: to offer a fully developed, high-performance, perfectly adapted solution, with availability expected by the end of 2026.

4- Propeller torsional vibration analysis on Lycoming O-360

This report presents an experimental study of torsional vibrations in a Lycoming O-360 engine / direct-drive propeller assembly. Vibratory torque measurements were carried out on the ground and in flight on several propeller configurations (aluminum, wood, multi-blade carbon, and 3-blade carbon). The results highlight significant resonances depending on the propeller type, and show that an optimized design can greatly reduce vibratory coupling.

Click here to discover the full report:

=> Experimental analysis of propeller torsional vibrations on Lycoming O-360 engine