E-Props : fabrication, blindage, équilibrage, tracking

Les hélices E-PROPS sont intégralement fabriquées en France(Sud-Est, Provence, près de Sisteron).

L'équipe de 52 ingénieurs et techniciens aéronautiques produit plus de 75000 pales en carbone par an.

1- Procédé de fabrication des hélices E-Props

2- Blindage de bord d'attaque

3- Equilibrage des hélices

4- Tracking

Toutes les pièces E-PROPS, pales, moyeux et cônes, sont en carbone + résine époxy.

Elles sont fabriquées selon le procédé appelé RTM (Resin Transfer Molding).

=> Voir description ici: FABRICATION DES HELICES E-PROPS

E-PROPS propose deux solutions pour renforcer ses pales carbone : un blindage en Titane (gamme d'hélices V20) ou un renfort en additif choc Nanostrength (gamme d'hélices V12 - plus en production depuis 2019 - et gamme d'hélices à pas fixe).

=> Voir description ici: BLINDAGE DE BORD D'ATTAQUE

E-PROPS blindage de bord d'attaque en Titane

Les hélices E-Props sont réputées pour leur grande légèreté, leur très faible moment d'inertie et leur équilibrage parfait. Elles sortent toutes des ateliers parfaitement équilibrées. Chez E-Props, chaque jeu de pales est équilibré avec son moyeu et son espaceur.

A noter: dans une hélice, les pales ne doivent pas faire forcément la même masse. Si vous avez des pales qui ne font pas la même masse, ce n'est pas grave. Ce qui compte pour un équilibrage parfait, c'est la répartition de la masse tout au long de la pale, c'est-à-dire le moment statique.

=> Voir explications ici: EQUILIBRAGE HELICES E-PROPS

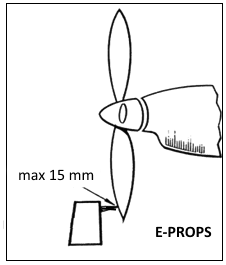

Le "tracking" est la différence de position longitudinale d'un saumon à l'autre (le saumon est le bout de la pale).

Sur les E-PROPS, la tolérance maximum de tracking est de 15 mm.

=> Voir détail ici: TRACKING HELICES E-PROPS

tracking max E-Props

L'équipe de 52 ingénieurs et techniciens aéronautiques produit plus de 75000 pales en carbone par an.

1- Procédé de fabrication des hélices E-Props

2- Blindage de bord d'attaque

3- Equilibrage des hélices

4- Tracking

1- Procédé de fabrication des hélices E-Props

Toutes les pièces E-PROPS, pales, moyeux et cônes, sont en carbone + résine époxy.

Elles sont fabriquées selon le procédé appelé RTM (Resin Transfer Molding).

=> Voir description ici: FABRICATION DES HELICES E-PROPS

2- Blindage de bord d'attaque

E-PROPS propose deux solutions pour renforcer ses pales carbone : un blindage en Titane (gamme d'hélices V20) ou un renfort en additif choc Nanostrength (gamme d'hélices V12 - plus en production depuis 2019 - et gamme d'hélices à pas fixe).

=> Voir description ici: BLINDAGE DE BORD D'ATTAQUE

E-PROPS blindage de bord d'attaque en Titane

3- Equilibrage des hélices

Les hélices E-Props sont réputées pour leur grande légèreté, leur très faible moment d'inertie et leur équilibrage parfait. Elles sortent toutes des ateliers parfaitement équilibrées. Chez E-Props, chaque jeu de pales est équilibré avec son moyeu et son espaceur.

A noter: dans une hélice, les pales ne doivent pas faire forcément la même masse. Si vous avez des pales qui ne font pas la même masse, ce n'est pas grave. Ce qui compte pour un équilibrage parfait, c'est la répartition de la masse tout au long de la pale, c'est-à-dire le moment statique.

=> Voir explications ici: EQUILIBRAGE HELICES E-PROPS

4- Tracking

Le "tracking" est la différence de position longitudinale d'un saumon à l'autre (le saumon est le bout de la pale).

Sur les E-PROPS, la tolérance maximum de tracking est de 15 mm.

=> Voir détail ici: TRACKING HELICES E-PROPS

tracking max E-Props